Introduction

Robotic arm technology has transformed dramatically, evolving from simple mechanical systems into intelligent, adaptable, and highly precise tools. Today’s robotic arms are reshaping industries like manufacturing, healthcare, space exploration, logistics, and more. Innovations in AI, connectivity, soft robotics, and simulation systems continue to push boundaries and redefine what robots can achieve.

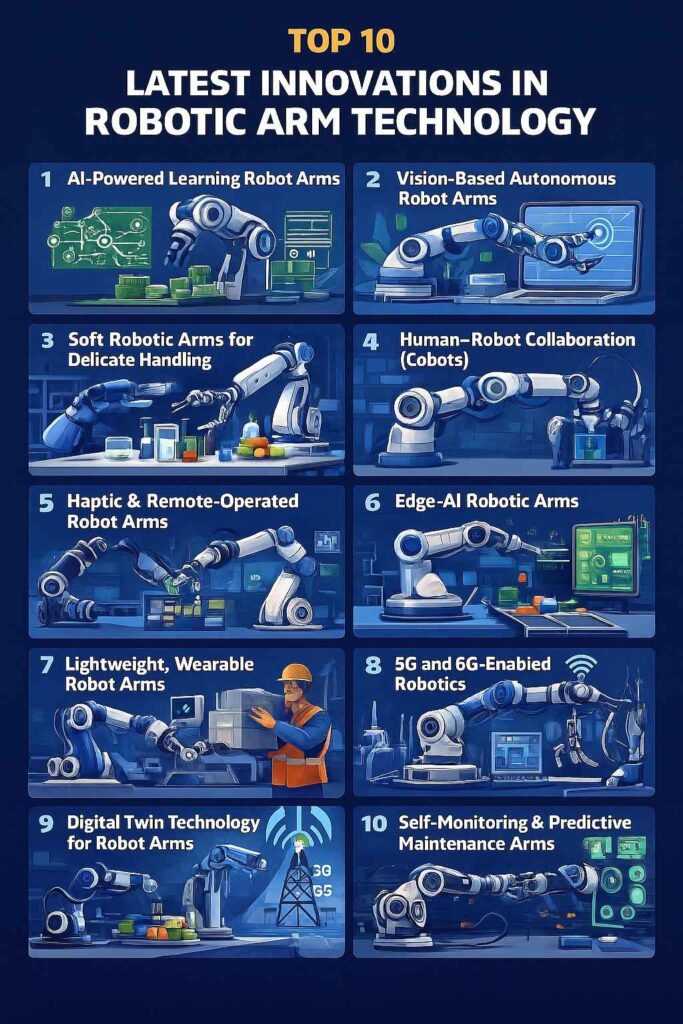

This article explores the top 10 latest innovations in robotic arm technology, explaining how each advancement works and why it is shaping the future of automation.

1. AI-Powered Learning Robot Arms

AI is driving the next era of robotic intelligence. Instead of relying solely on rigid, pre-programmed motion sequences, modern robotic arms use learned policies—behaviors developed through machine learning, demonstration, or simulation.

How It Works

- Neural networks analyze motion data and refine tasks via trial-and-error.

- Robots adapt to variations in the environment.

- Policies evolve, enabling robots to handle previously unseen situations.

Benefits

- Less manual programming

- Fast adaptation to new tasks

- Better performance in complex workflows

2. Vision-Based Autonomous Robot Arms

Computer vision has given robotic arms the ability to “see” and interpret their surroundings using cameras and AI detection models.

Why It Matters

- Enables accuracy when handling irregular objects

- Reduces human supervision

- Allows robots to interact dynamically with their environment

Where It’s Used

- Precision manufacturing

- Automated sorting

- Medical labs

- Electronics assembly

3. Soft Robotic Arms for Delicate Handling

Soft robotic arms mimic biological muscles using flexible materials such as silicone or fluid-driven actuators.

Advantages

- Safe for close human interaction

- Perfect for handling sensitive or fragile items

- Reduces risk of damage

Applications

- Hospital assistance robots

- Food packaging

- Lab automation

- Biotech research

4. Human–Robot Collaboration (Cobots)

Cobots are designed to operate safely beside humans, using advanced sensors and force-limiting mechanisms.

Key Features

- Easy and intuitive programming

- Built-in safety systems

- Versatile across industries

Enhanced Benefit (Revised as Suggested)

Enables hybrid workflows where humans and robots maximize each other’s strengths—humans provide creativity and judgment, while robots provide precision and stamina.

5. Haptic & Remote-Operated Robotic Arms

Haptic feedback allows operators to “feel” the environment a robot is interacting with, creating precision-level control.

Why It’s Important

- Enables delicate surgical procedures

- Safe operations in dangerous environments

- Improves control accuracy

Use Cases

- Telemedicine

- Nuclear facilities

- Deep-sea exploration

- Space missions

6. Edge-AI Robotic Arms

Edge AI allows robotic arms to process data directly on-device rather than relying on cloud servers.

Benefits

- Instant response

- Higher privacy and security

- Reduced dependence on internet connectivity

Applications

- High-speed quality checks

- Autonomous sorting lines

- Real-time robotics in factories

7. Lightweight, Wearable Robot Arms (Updated for Clarity)

While similar to exoskeletons, this category focuses on wearable robotic arms that extend human abilities, blending human intelligence with robotic strength.

Why They Matter

- Reduce strain and fatigue

- Enhance lifting or precision tasks

- Assist in rehabilitation and therapy

Industries Benefiting

- Warehousing

- Aerospace

- Healthcare

- Construction

8. 5G and 6G-Enabled Robotic Arms (Now Clearly Defined)

Ultra-low-latency networks—meaning communication delays of just milliseconds—enable near-instant robotic response, essential for high-risk or remote operations.

Advantages

- Near-zero delay remote control

- Stable operation of multiple robots simultaneously

- Enhanced safety and precision

Use Cases

- Remote surgery

- Defense robotics

- Smart factories

- High-speed automation lines

9. Digital Twin Technology for Robotic Arms

A digital twin is a virtual model that mirrors a real robotic arm’s behavior.

Why It’s Transformative

- Allows simulation before real deployment

- Predicts failures early

- Reduces downtime and errors

Applications

- Smart manufacturing

- Robotics design

- Predictive maintenance

10. Self-Monitoring & Predictive Maintenance Arms

The newest robotic arms monitor their own health using built-in sensors and AI algorithms.

What They Can Detect

- Vibration anomalies

- Temperature changes

- Wear patterns

- Tool misalignments

Benefits

- Fewer breakdowns

- Extended equipment lifespan

- Lower maintenance costs

Future Outlook

The next generation of robotic arms will combine:

- More human-like dexterity

- Autonomous learning in real-world environments

- Fully modular robot systems

- Swarm robotics for collaborative tasks

- Advanced soft robotic muscles

These innovations point to a future where robots and humans work side-by-side, enhancing productivity and safety across all industries.

Conclusion

The evolution of robotic arm technology is reshaping the world of automation. From AI-driven learning systems to digital twins and ultra-low-latency networks, each breakthrough increases the versatility, intelligence, and safety of robotic systems.

Robotic arms are no longer just tools—they are partners in production, healthcare, research, and exploration.

Which of these robotic arm innovations do you think will have the biggest impact in the next few years? Share your thoughts in the comments!

For more Insights related to other topic visit : Quillorbit.